How to Choose Plastic Crushing Machine?

Choosing the right plastic crushing machine is a critical step if you want to effectively utilize your plastic waste and increase its recycling potential. In this guide; we will examine in detail what plastic crushing machines are, their technical features, their areas of use and what you should pay attention to during the purchasing process.

Every business needs are different: there can be big differences between a small-scale plant and a large factory in terms of utilization capacity, energy consumption or maintenance requirements. In this article, we will focus on topics such as plastic crushing machine prices, technical specifications of the models, maintenance tips and environmentally friendly advantages. We will also provide information that will help you make the right decision in machine selection with real examples from different sectors.

By the end of the article, you will have learned the machine comparison criteria and will be able to draw up an investment plan equipped for long-term efficiency. Let’s get started – optimize your recycling processes with a plastic crushing machine and make the transition to sustainable production.

What is a Plastic Crushing Machine?

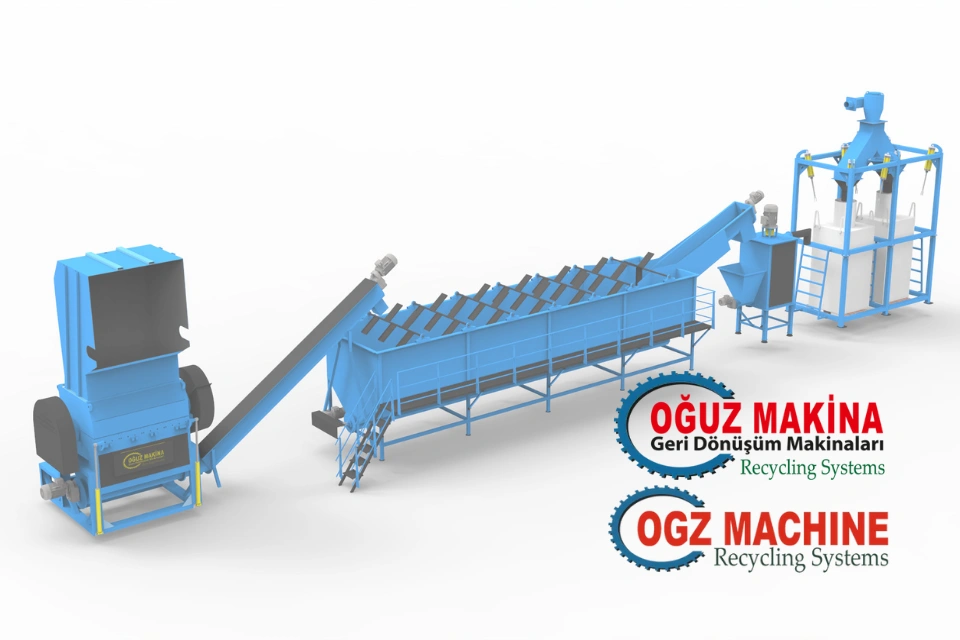

Plastic crushing machine is an industrial equipment that makes different types of plastic materials suitable for the recycling process by turning them into smaller pieces. These machines transform hard and bulky plastics into granules, flakes or powder, saving volume and transforming them into a reprocessable form.

Working Principle

After the plastic is placed in the feeding hopper at the front of the machine, it is cut or broken with the help of rotating knives. The material then passes through the sieve system and exits in the desired size. Some models can also be automatically conveyed with vacuum or conveyor systems.

Basic Components

- Motor: Drives the rotational movement and the blades.

- Rotor & Blade: Moving and fixed parts responsible for the cutting process.

- Sieve: Controls the size of the material coming out.

- Body: Usually made of steel, determines durability.

The machine is available in various models according to capacity, rotor type, motor power and number of blades. This structure makes it adaptable for different types of plastics.

Advantages of Plastic Crushing Machine

Recycling Efficiency

Plastic crushing machines make waste much faster and more efficiently processable. This improves the overall performance of the recycling lines.

Energy Savings and Low Maintenance

Modern machines consume less energy thanks to optimized engine systems. In addition, maintenance times are reduced with automatic cleaning systems.

Environmental Contributions

As broken plastics become reusable, the rate of plastic waste released into the environment decreases. This is an important contribution to reducing the carbon footprint.

Usage Areas According to Plastic Types

Material Base:

- PE (Polyethylene): Bags, bottles, containers

- PP (Polypropylene): Automotive parts, sacks

- PVC (Polyvinyl Chloride): Pipes, window profiles

- PET (Polyethylene Terephthalate): Soft drink bottles

Sectoral Use:

- Recycling facilities

- Automotive spare parts production

- Packaging industry

- White goods & electronics

- Building sector (PVC crushing)

Types of Plastic Crushing Machines ve Modelleri

Single Rotor Shredder

Double Rotor Shredder

Plastic Crushing Machine

Technical Specifications and Performance

Capacity

The hourly kg/h rate is the selection criterion. There are different models between 100 kg/h and 2000 kg/h.

Engine Power

It usually ranges between 5.5 kW and 75 kW. Energy consumption increases with the increase in power.

Rotor and Blade Structure

Rotors and blades made of hardened steel for long life.

Sound Level & Insulation

It is between 70-85 dB in industrial type machines. 20 percent sound reduction is possible with acoustic cabins.

Plastic Crushing Machine Selection Criteria

- Throughput: How much plastic will be broken?

- Type of material: Hard plastic or thin film?

- Safety: Emergency stop, cover sensors?

- Energy consumption: KWh/ton values should be compared.

Installation and Operation

- Installation: Floor fixing, electrical installation

- Operator Training: Safety rules, daily checklists

- Testing & Commissioning: Empty run, test under load

Maintenance and Longevity

- Knife Sharpening: After 50-100 hours of operation

- Engine Maintenance: Bearing check every 6 months

- Sieve Cleaning: Weekly check for blockages

Sample Applications

- Automotive Parts Recycling: Crushing and granulating of PP bumper parts

- Packaging Waste Crimea: Centralized recovery of PE bags

Key Takeaways

- Plastic crushing machines contribute to recycling.

- Capacity, motor power, rotor type are critical selection criteria.

- Regular maintenance extends the life of the machine.

- Technical inspection is essential for second-hand purchases.

- The appropriate model for each type of plastic is different.

Conclusion and Call

Buying a plastic crushing machine requires proper analysis and planning. With the information you have learned in this guide, you can choose the most suitable model for your business, increase your recycling capacity and save money in the long run.

We recommend that you seek technical advice from an expert before purchasing your machine. If you have questions you can contact us or request a demo. Feedback will come, take the first step today.

FAQ – Frequently Asked Questions

1. What does a plastic crushing machine do?

It turns plastic waste into granules and makes them suitable for recycling.

2. Which types of plastics can it be used for?

is suitable for thermoplastics such as PE, PP, PVC, PET.

3. How is the energy consumption?

It varies between 5-50 kWh/ton depending on the model.

4. How do prices vary?

Prices vary depending on engine power, capacity, brand and additional features.

5.What is the maintenance period?

Daily check, weekly cleaning and general service is required every 6 months.

Message to the Reader

Do you think this article was useful? If you need more technical information about the plastic crushing machine, you can write in the comments or contact us.

Don’t forget to share this article on social media to reach more people! Is the choice or the technical comparison the most challenging issue for you? Write in the comments!